Location

Belgium

Industry

Food

Enhanced Durability

The Schegler Fasto’s design, with its thick impeller and liners, ensures long-lasting performance in abrasive conditions.

Reduced Wear

Operating at lower RPMs minimizes wear and extends operational life in critical sugar processing tasks.

Comprehensive Service

Vaikon offers full engineering support, installation, and commissioning, ensuring a smooth transition.

Operational Efficiency

Significant reductions in maintenance issues and enhanced efficiency, leading to uninterrupted and cost-effective sugar production.

Challenge

A leading sugar factory was facing repeated disruptions due to frequent failures of their slurry pump used for the filter press feed. The existing Ensival pump struggled to handle the challenging nature of the slurry, leading to heavy leakage, rapid wear, and overall reliability issues. Vaikon was called in to provide a solution that would not only withstand the abrasive conditions but also reduce the frequency of maintenance and extend the operational lifespan of the filter press feed system.

Solution

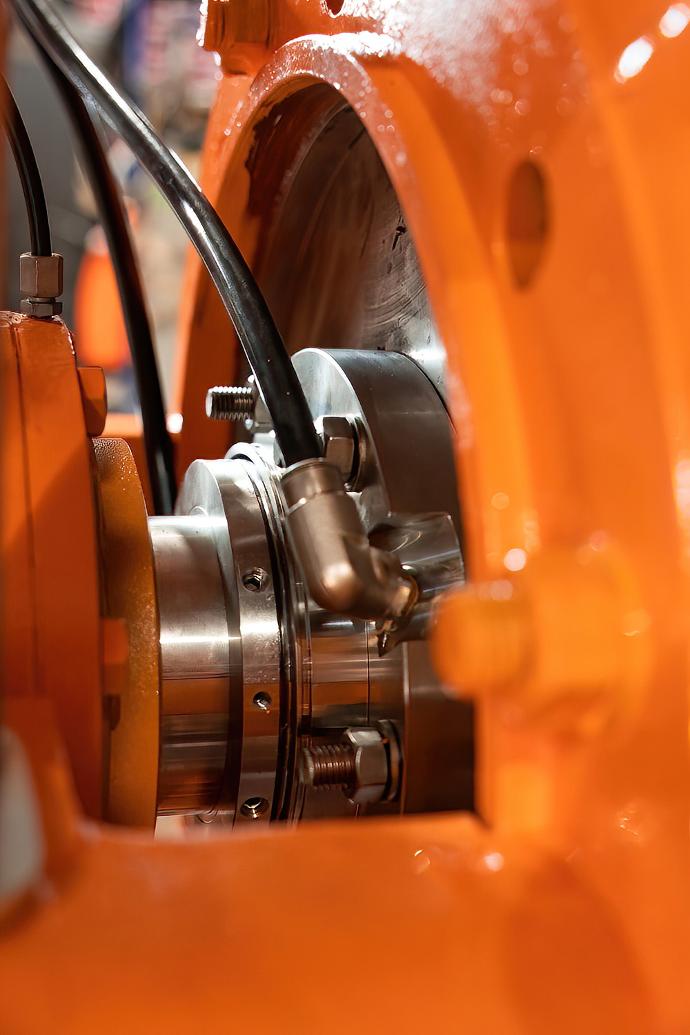

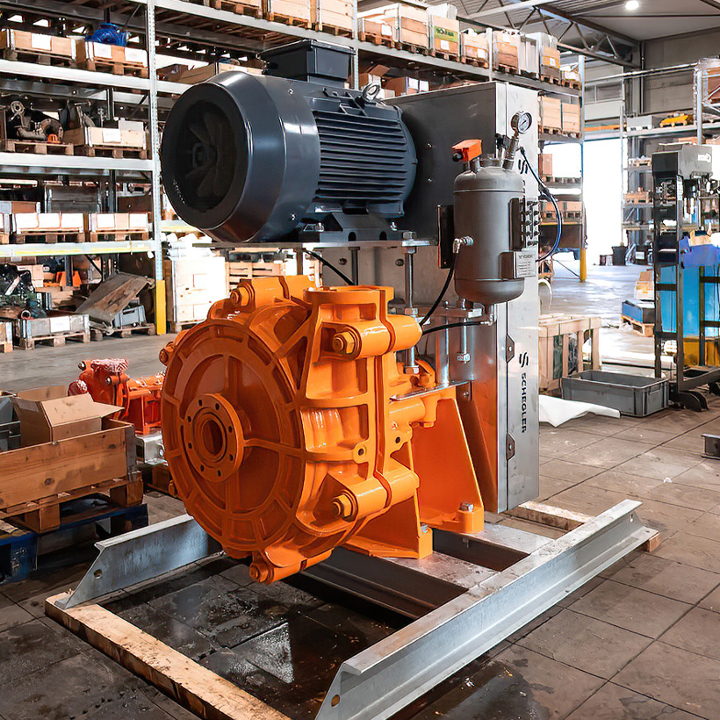

After a thorough assessment, Vaikon recommended the Schegler Fasto 4x3 pump, designed for heavy-duty tasks. This new pump operates at a lower speed compared to the previous model (1100 RPM instead of 1950 RPM), significantly reducing wear. Its robust design, including a thick impeller, durable liners, and a high shaft stiffness ratio, ensures longer bearing life and reduced vibrations.

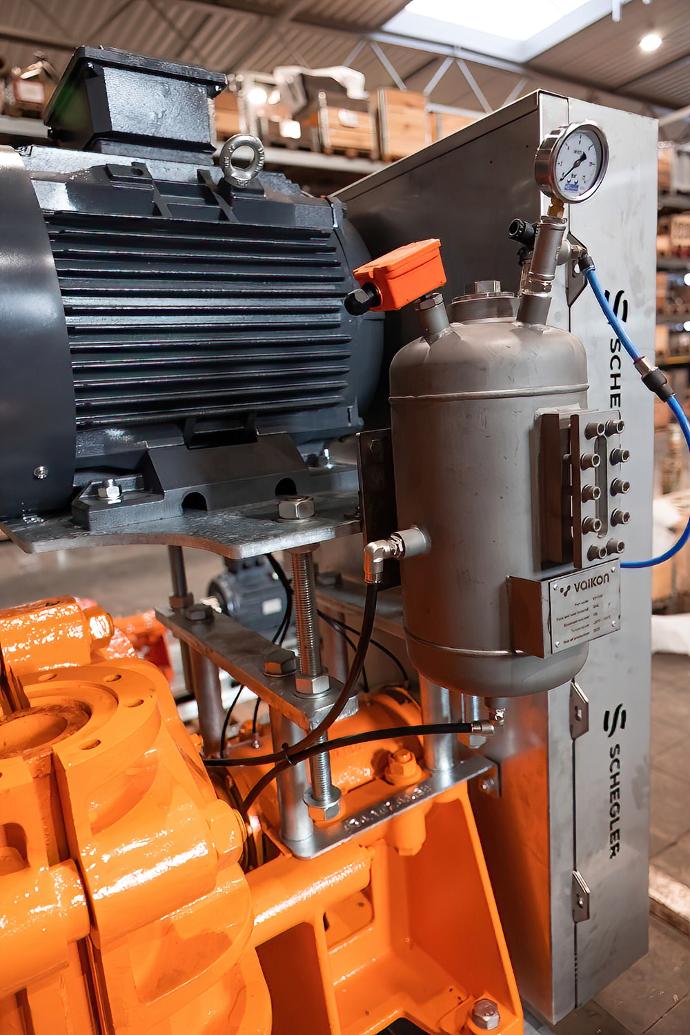

In addition, the pump was fitted with heavy-duty bearings and a Brayston double mechanical seal, both known for their durability in abrasive applications. A thermosiphon vessel was mounted on the pump base, making on-site installation easier and more efficient.

Result

The installation of the Schegler Fasto pump led to a noticeable boost in reliability. Maintenance requirements were drastically reduced, the pump’s lifespan increased, and the factory’s overall operational efficiency improved. Vaikon provided end to- end support, including engineering expertise, installation, and commissioning, ensuring a smooth transition.

Thermosiphon vessel temporarily mounted lower for transport.

Thermosiphon vessel temporarily mounted lower for transport.