Location

France

Industry

Metal

Improved Durability

The Schegler Vigor 8x6’s design, especially for abrasive materials, offers outstanding performance in demanding conditions.

Advanced Sealing

System The Brayston double mechanical seal, together with the thermosyphon feeding system, provides superior reliability, addressing the issue of premature seal failures.

Operational Stability

The new pump and sealing system led to fewer failures and reduced maintenance requirements.

Rapid Spare Part Availability

Vaikon guarantees short lead times for spare parts, thanks to our extensive stock, ensuring uninterrupted operations.

Challenge

A world-class metal processing company was facing operational challenges with their existing Schabavert C200 pump. This pump was crucial for filling a filter press with Goethite slurry, which had a specific gravity of 1.19, with a start flow rate of 500 m³/h and an end pressure of approximately 4 bar. However, the pump frequently encountered premature seal failures and other operational inefficiencies, and on top of this problem, the company was also grappling with frustratingly long lead times for spare parts. This led to increased maintenance costs and production disruptions. The task was to replace the Schabavert C200 pump with a more suitable option and to enhance the overall efficiency and reliability of the pumping operation.

Solution

Vaikon proposed a comprehensive solution:

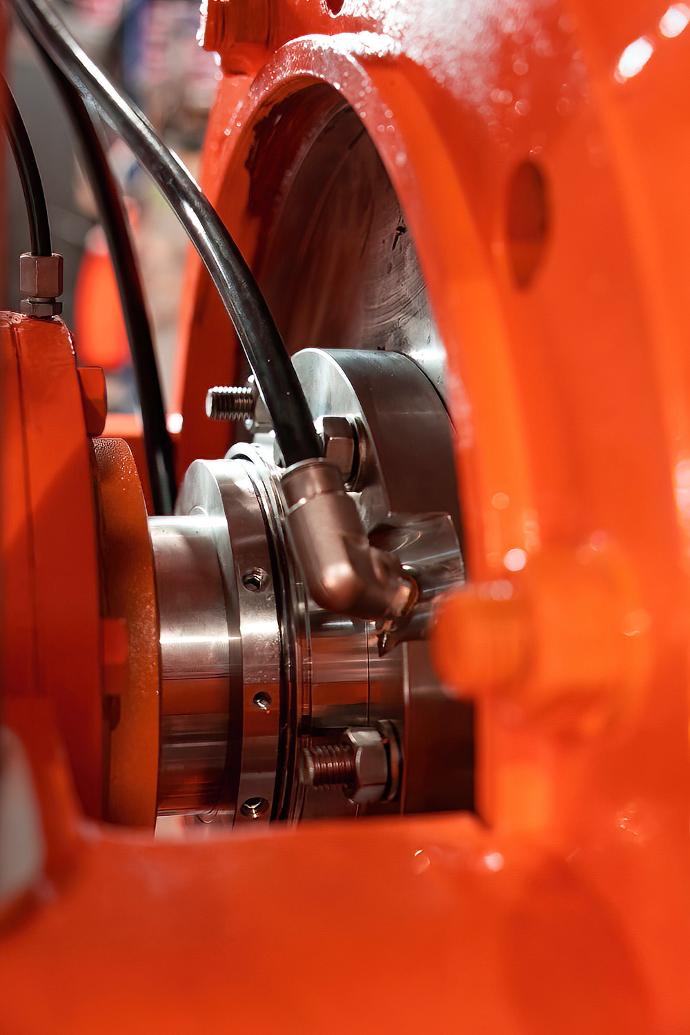

- Pump Replacement: The Schabavert C200 pump was replaced with a Schegler Vigor 8x6 pump, selected for its compatibility with abrasive materials like Goethite slurry. The Schegler Vigor 8x6 featured a rubber liner specifically designed for such challenging applications, promising improved durability, and performance.

- Seal Enhancement: To address the premature seal failure, Vaikon opted for the Brayston Double Mechanical Seal. This seal provides enhanced reliability and longevity, perfectly suited to the demanding conditions of Goethite slurry.

- System Upgrade: A standalone thermosyphon feeding system was installed. This system utilized the principles of natural convection to circulate the sealing liquid, maintaining optimal pressure without the need for external pumps or complex controls.

- Efficient Integration: Existing bases were repurposed, allowing the new pumps to be seamlessly integrated into the current setup with minimal modifications, ensuring a smooth and cost-effective installation.

Result

The solution significantly enhanced the performance of the metal processing company’s operations:

- Increased Reliability: The new pump and sealing system significantly improved the reliability of the pumping operation. The issues of premature seal failure were resolved, leading to fewer pump failures and reduced maintenance.

- Long-Term Benefits: The new system not only met the immediate needs of the company but also promised longer-term operational stability and reduced downtime, marking a significant step forward in their production capabilities.

The implementation of the Schegler Vigor 8x6 pump and Brayston Double Mechanical Seal not only enhanced the pump’s performance and reliability but also addressed the issue of long spare part lead times.